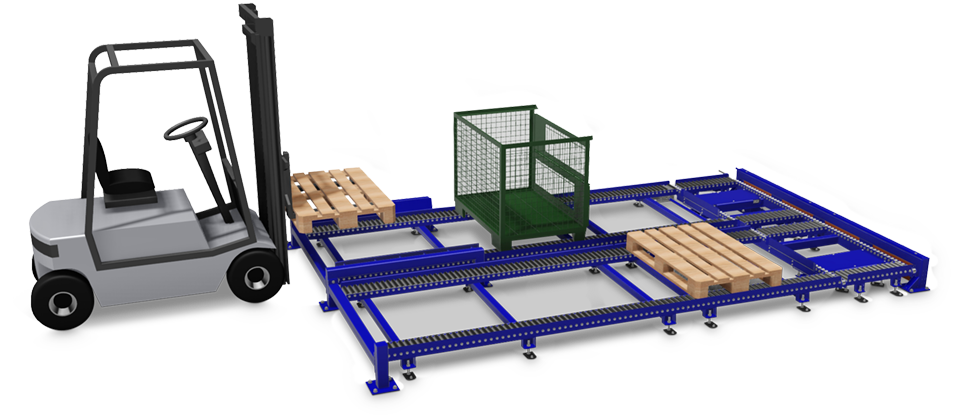

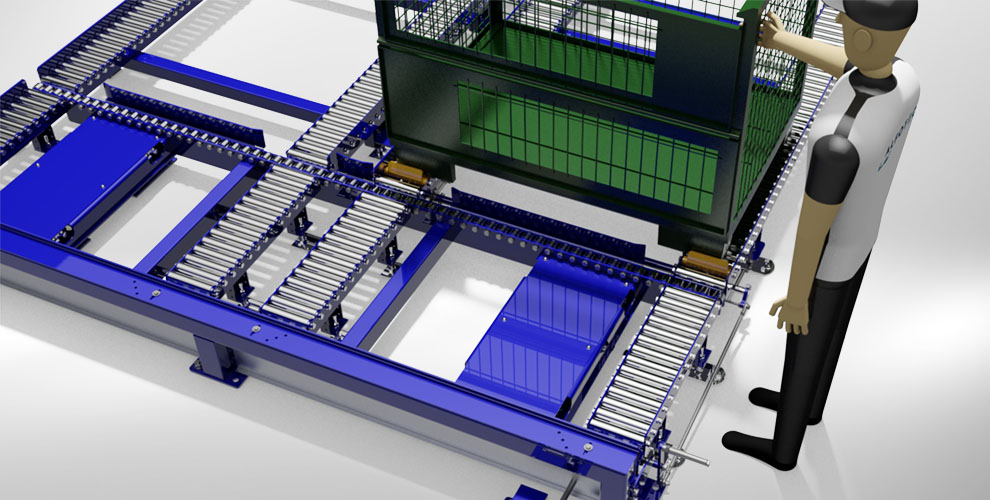

Non-driven container station

Delivery period: April 2016

The client:

Our customer is a medium-sized family business with headquarters in Germany. As a supplier to the automotive industry it develops and produces locking, handle and hinge systems which are installed in flaps, doors and seats of almost all internationally known car brands.

The task:

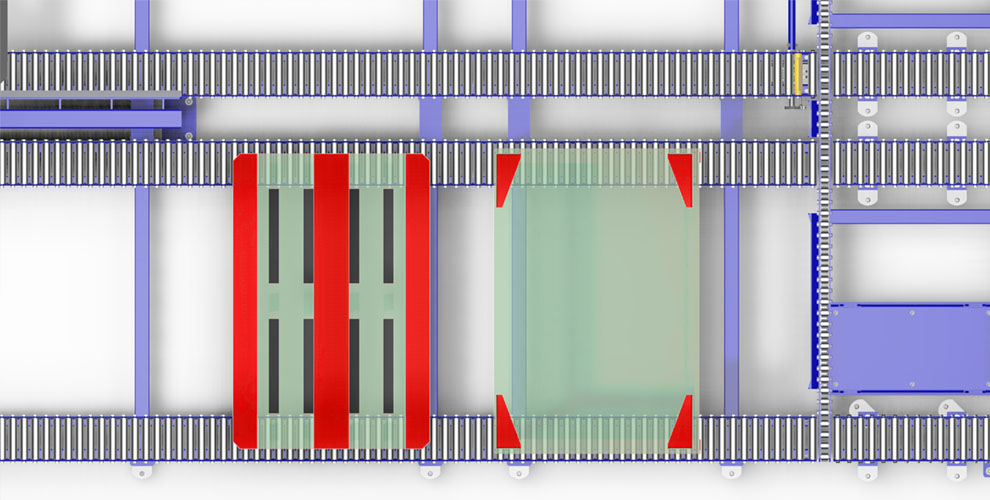

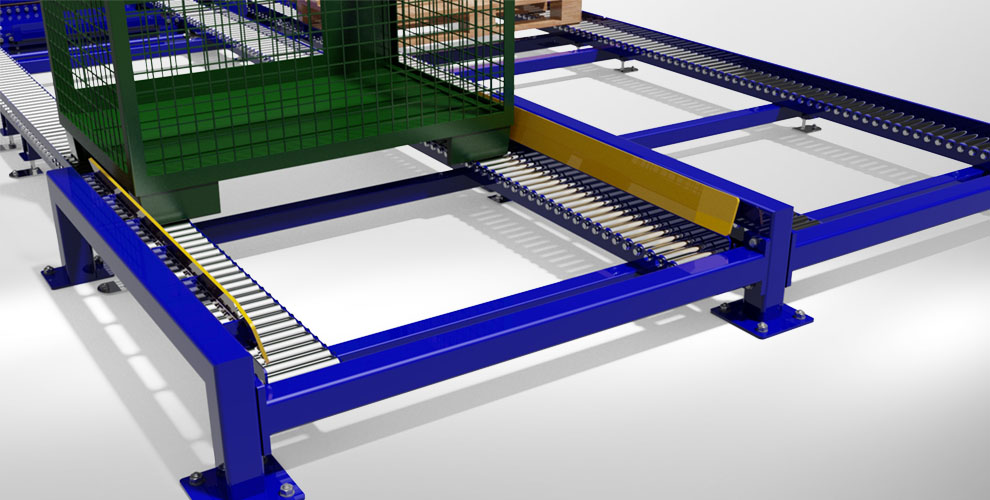

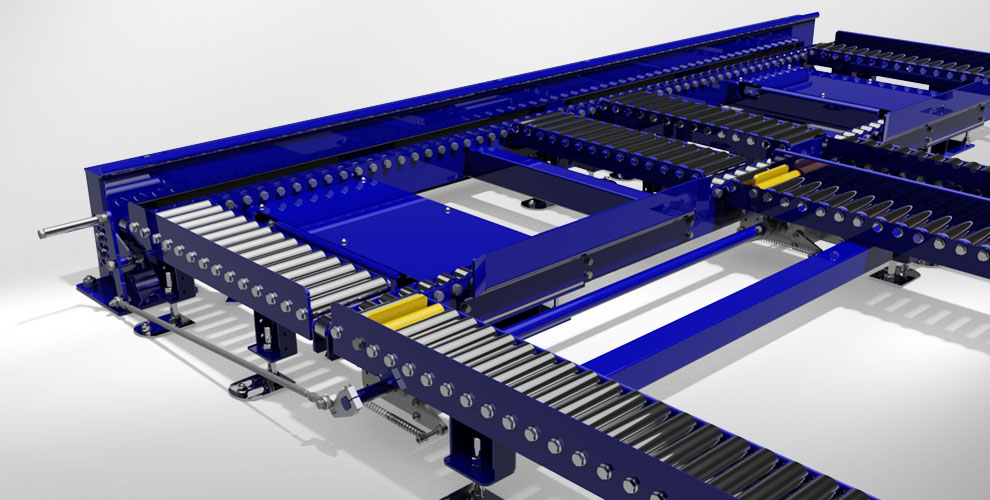

The customer commissioned us to manufacture and install three non-driven conveyor systems with buffer zones, so-called container stations. Within the production process, these should be able to transport and buffer manually filled Euro pallets, lattice boxes as well as difficult to transport containers with a small contact surface (e.g. plate foot 110 x 110 mm) at the same time.

Features

- Conveying Elements: Strand conveyor

Converter and change of direction

Storage techniques - Convey Goods: Pallets

mesh pallets and special containers - Industry: Metal / Automotive