Assembly line assembly of office desks

Delivery period: November 2019

The client: REISS Büromöbel GmbH

The company REISS Büromöbel GmbH is an innovative manufacturer of modern office furniture and specialises in particular in ergonomic workstations. In addition to ergonomics, it also pays attention to acoustic emissions, hygiene and sustainability in production and the entire company. Founded in 1882, the company initially sold office aids as well as surveying equipment before developing the first sitting/standing table in Germany in 1910 by manufacturing drawing machines and office furniture. At the end of the 20th century, the upheaval and focus on office furniture took place, which today makes REISS an established company for office workplaces.

The task: An ergonomic assembly line

In a new plant, which the REISS company built in Lausitz, the innovative but also ergonomic idea of the company was to be continued. For this reason, a work-friendly assembly line was conceived as a production line, on which the heavy tables were to be assembled, tested, packed and assembled ready for dispatch step by step. These processes were to be carried out by assembly workers on the conveyor system without having to transport the bulky tables under their own power. In the assembly sequence, the table should be brought to different working heights in different process stages. It should be made as comfortable as possible for the employees to attach the various attachments of the table extension stages, such as electrical height adjustments, cable ducts, leg room panels, etc. and to subject them to a function test. As the ever-growing trend towards individualisation was also taken up by REISS, they have a large number of additional accessories in their portfolio. For this reason, the assembly line series already divided into “electromotive stand-up/sit-down workstations” and “standard tables” was again doubled for the electromotive workstations to be individualised. In addition, there was the challenge that initially only a first expansion stage, which only provided for the electrical assembly twice, but not the remaining steps, of the system was to be erected before the system had to be easily expandable in a future step.

Clients

Features

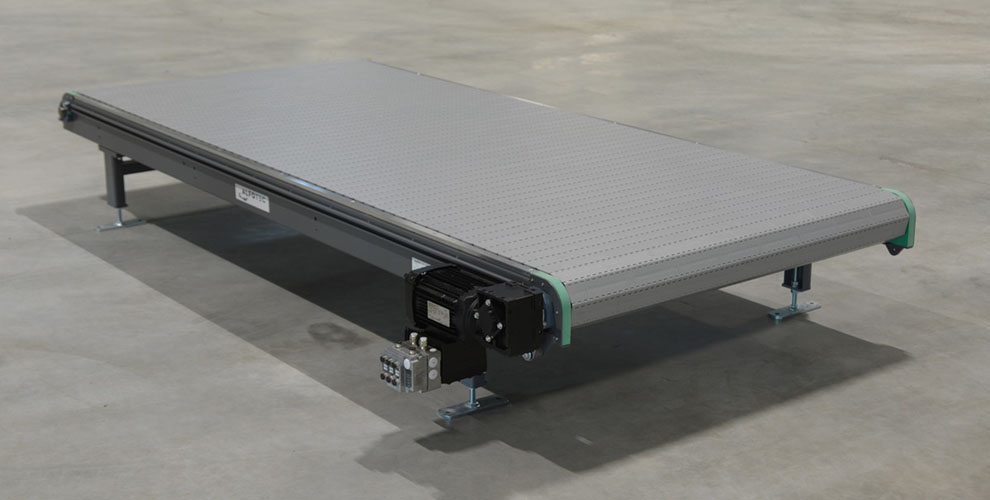

- Conveying Elements: Roller conveyor

Belt conveyor

Converter and change of direction

Lift table - Convey Goods: Office desks

- Industry: Furniture