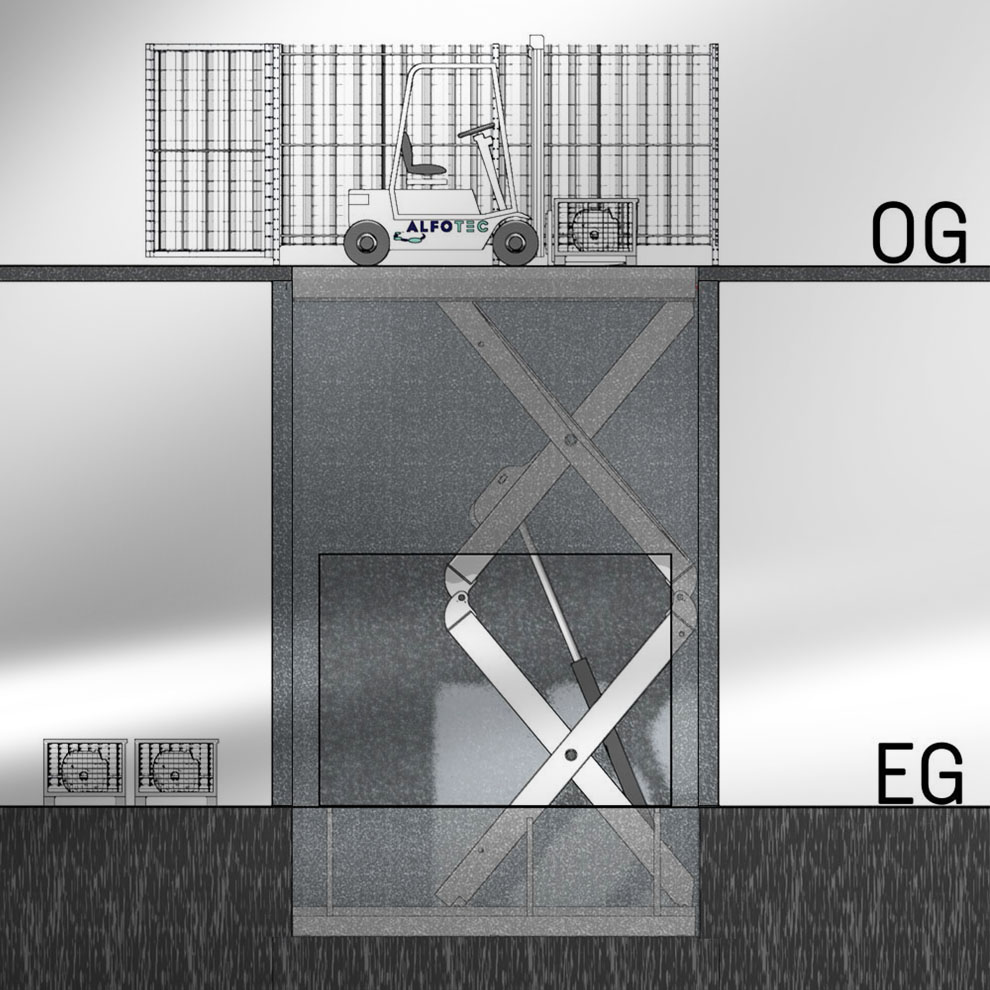

Forklift truck on 8 t lifting table

Delivery period: September 2014

Die KSM Castings Group

The KSM Castings Group is an international development partner and producer of light metal castings for the automotive industry.

Requirement: Transport of castings between two floor levels

At the Radevormwald plant of KSM Castings Group GmbH, parts were to be transported between the “casting production” and “casting machining” floors. What was unusual about this was that the material to be transported did not consist solely of the castings, but had to include an entire forklift weighing several tons, including lattice boxes and pallets.

Technical details: Vertical double scissor lift table according to DIN EN 1570

| Platform length: | 4.000 mm |

| Platform width: | 3.000 mm |

| Resilience: | 8.000 kg |

| Overall height: | 1.300 mm |

| Lift: | 5.350 mm |

| Lift time: | ca. 98 sek |

| Performance: | 2 x 4,6 KW |

| Operating voltage: | 3 x 400 / 50 V/Hz |

| Valve voltage: | 24 VAC |

Clients

Features

- Conveying Elements: Lift table

- Convey Goods: Individual castings on pallets

lattice boxes

forklift - Industry: Metal / Automotive